How Much Simpler Can You Get

This Wheeler* incandescent streetlight has just three main components.

1. The head (which holds the lamp socket) is a one piece aluminum casting. At the left is an interior view of the head with the socket and wires removed. There is nothing inside but a few lugs with threaded mounting holes for attaching the socket. An adapter ring that screws into the bottom of the head is presently frozen to the head by corrosion. The head is held onto a bracket arm by a U-shaped bolt similar to those that hold automobile muffler pipes together. This head looks like a NEMA standard head but is not. It does not have fins at the bottom rim to accept a variety of snap on reflectors.

2. The lamp socket (center of photo) is mounted on sliding rails so that the height of the lamp filament can be adjusted. Streetlight manufacturers publish guidelines for positioning of the lamp. For this style of reflector it has been suggested that the lamp filament be even with the side edges

3. The reflector (top of photo) is a single piece of stamped sheet aluminum. This reflector is lacquer coated to reduce corrosion. It is fastened with four small bolts and with washers that act as retaining tabs. There is no glass cover.

Streetlights give off a lot of heat, especially if high wattage lamps are used. The head is several inches in size so that it has a lot of surface area through which heat rising from the lamp can be radiated out to the surrounding air. Otherwise wire insulation would melt and burn.

Mercury/Sodium Conversion

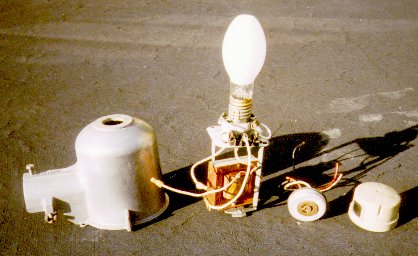

This modern ballast and frame is used to convert an incandescent luminaire to mercury vapor. It fits inside a standard incandescent luminaire head, displacing the original lamp socket. Shown here is a 100 watt 240 volt ballast. Ballast conversion kits for other sizes of mercury and sodium lamps up to about 200 watts are also available. These are the same types of ballasts found in commonly available yard lights. This ballast is not a transformer since it has only one coil of wire. Its sole purpose is to limit the flow of current through the lamp without dissipating much measurable and therefore billable energy.

The 100 watt mercury lamp shown here can be used to replace a 295 (or 300) watt 4000 lumen incandescent lamp and reduce energy costs, or to replace a 92 (or 75) watt 1000 lumen incandescent lamp and provide more light.

Also shown is the photocontrol socket (second from right) which mounts in the top of the head, and a typical photocontrol (far right).

This ballast unit is compatible with existing reflectors and refractors. It adds an additional six pounds of weight to the fixture. As a contrast between today's and yesteryear's magnetic coil technology, an older ballast (for a 250 watt lamp) in this writer's collection, probably of 1950's vintage, weighs 32 pounds..

* Streetlight made ca. 1950 by the Wheeler Reflector Co., Boston, Mass.

Back to streetlight main

page

Go to index of other

topics

Contact us

All parts (c) Copyright 1998-2009, Allan W. Jayne, Jr. unless otherwise noted or other origin stated.

If you would like to contribute an idea for our web page, please send us an e-mail. Sorry, but due to the volume of e-mail we cannot reply personally to all inquiries.